Unveiling the Potential of 3D Concrete Printing

Cementitious 3D construction printing (3DCP), commonly known as 3D concrete printing, stands at the forefront of additive manufacturing, capable of crafting bespoke items, from intricate architectural furniture to extensive fully-printed buildings and civil infrastructure. This cutting-edge technology introduces a realm of possibilities, enabling the creation of objects beyond the constraints of conventional concrete casting methods.

Sikacrete® 3D Material Solutions

Sika, a trailblazer in the construction industry, harnesses the power of Sikacrete® 3D material solutions for precise and rapid concrete printing, aligning seamlessly with project specifications. This advancement signifies a departure from traditional construction methodologies towards a digitalized future, where innovation enhances productivity and introduces unparalleled design flexibility.

Digitalization Reshaping Construction Practices

For decades, reinforced concrete has been the stalwart of cost-effective construction. However, the integration of digital technology, exemplified by 3D concrete printing, propels the industry towards heightened efficiency, time-saving measures, and the delivery of truly distinctive structures. Sika positions itself as a driving force behind this transformative shift, offering avant-garde 3D concrete printing materials and solutions.

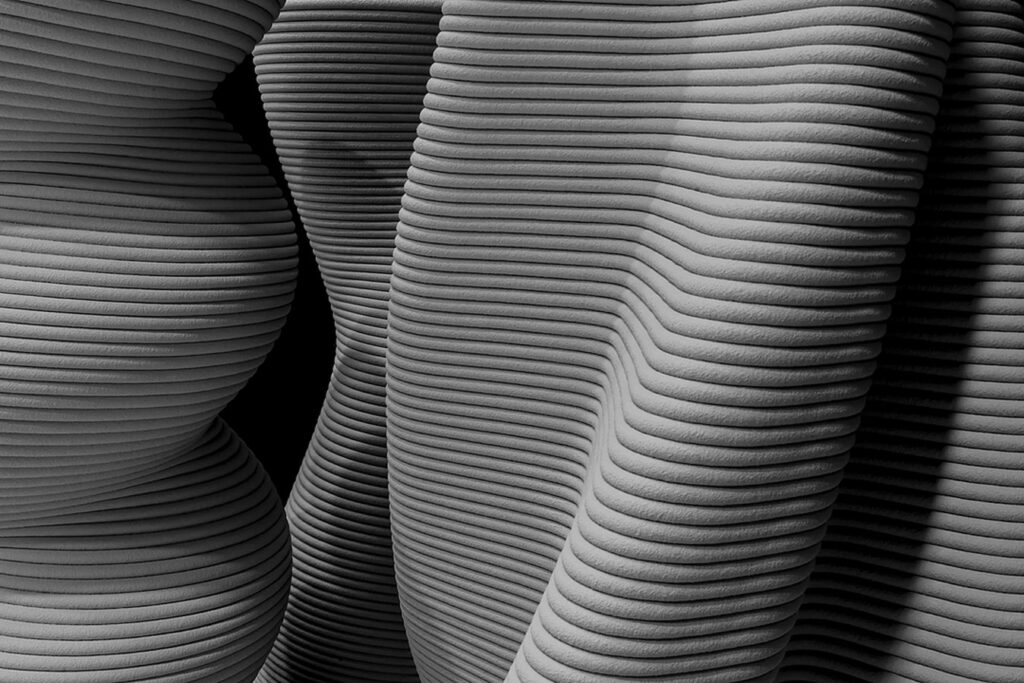

The Mechanics of 3D Concrete Printing

The process involves mounting a print head or nozzle onto a robotic arm or gantry. This nozzle, connected to a pump via a hose pipe, meticulously prints layers of concrete, allowing for intricate designs and structural complexities. Additions or admixtures can be incorporated to modify the material properties, showcasing the versatility of Sika’s 3DCP solutions.

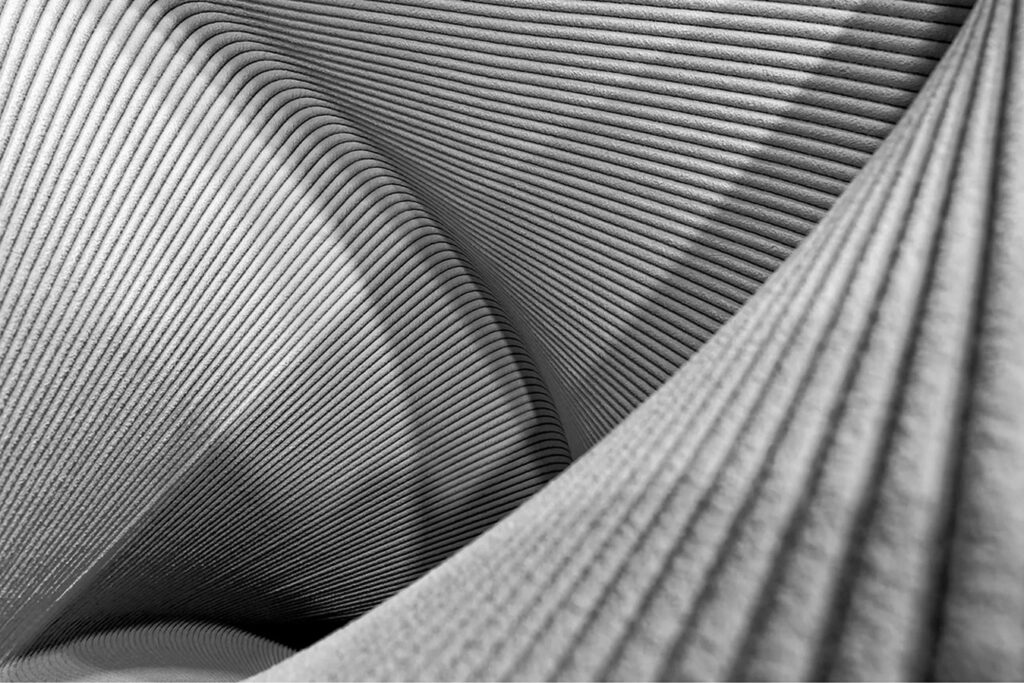

Essential Equipment for 3D Concrete Printing

The key equipment includes a positive action pan mixer for cementitious materials, a pump for continuous conveyance of freshly mixed material, an adequate length of pipe connecting the pump and print head, a robot arm or gantry equipped with control software, the print head or nozzle, and specialized software translating 3D computer models into machine programs, often referred to as slicing.

Sika’s Comprehensive Support for 3D Concrete Printing

Sika goes beyond providing innovative products; it offers a holistic approach to support those venturing into or enhancing their 3D concrete printing endeavors. Their Sikacrete® 3D solutions, coupled with technical expertise, encompass a spectrum of offerings, adding value to every phase of a project. From concrete admixtures to grouting, leveling, protection, sealing, bonding, strengthening, and fixing, Sika’s compatible products augment and elevate any 3D concrete printing project.

Pioneering Collaborations for Future Advancements

Actively seeking partnerships, Sika aims to develop materials that seamlessly integrate with diverse 3D concrete printing equipment. This collaborative approach underscores Sika’s commitment to fostering advancements in construction technology, ushering in a new era of possibilities in the realm of 3D concrete printing.